DIN912 H59 H62 Brass Hex Socket Cup Head dunƙule

DIN912 H59 H62 Brass Hex Socket Cup Head dunƙule

Bayani

SANARWAMartani

SANARWAMagana

SANARWABayarwa

SHIRYE SHIRYE SHIRKA

10000+ SKU a cikin sito

Mun ƙaddamar da abubuwan RTS:

70% abubuwan da aka kawo cikin kwanaki 5

80% abubuwan da aka kawo cikin kwanaki 7

90% abubuwan da aka kawocikin kwanaki 10

Babban umarni, da fatan za a tuntuɓi sabis na abokin ciniki

| d | M1.4 | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | |

| P | M zaren | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 |

| Zare mai kyau | / | / | / | / | / | / | / | / | 1 | 1.25 | 1.5 | 1.5 | 1.5 | 2 | 2 | |

| Zare mai kyau sosai | / | / | / | / | / | / | / | / | / | 1 | 1.25 | / | / | 1.5 | 1.5 | |

| b | Ƙimar magana | 14 | 15 | 16 | 17 | 18 | 20 | 22 | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 |

| dk | Max (Smooth) | 2.6 | 3 | 3.8 | 4.5 | 5.5 | 7 | 8.5 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 |

| Max (Knurl*) | 2.74 | 3.14 | 3.98 | 4.68 | 5.68 | 7.22 | 8.72 | 10.22 | 13.27 | 16.27 | 18.27 | 21.33 | 24.33 | 27.33 | 30.33 | |

| Min | 2.46 | 2.86 | 3.62 | 4.32 | 5.32 | 6.78 | 8.28 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | 29.67 | |

| ds | Max | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Min | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | |

| k | Max | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Min | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.7 | 7.64 | 9.64 | 11.57 | 13.57 | 15.57 | 17.57 | 19.48 | |

| s | Na suna | 1.3 | 1.5 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 14 | 17 |

| Min | 1.32 | 1.52 | 1.52 | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 12.032 | 14.032 | 14.032 | 17.05 | |

| Max | 1.36 | 1.56 | 1.56 | 2.06 | 2.58 | 3.08 | 4.095 | 5.14 | 6.14 | 8.175 | 10.175 | 12.212 | 14.212 | 14.212 | 17.23 | |

| t | Min | 0.6 | 0.7 | 1 | 1.1 | 1.3 | 2 | 2.5 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Tsawon zaren = b | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| d | (M22) | M24 | (M27) | M30 | (M33) | M36 | M42 | M48 | M56 | M64 | M72 | M80 | M90 | M100 | |

| P | M zaren | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 6 | 6 | 6 | 6 |

| Zare mai kyau | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Zare mai kyau sosai | 1.5 | / | / | / | / | / | / | / | / | / | / | / | / | / | |

| b | Ƙimar magana | 56 | 60 | 66 | 72 | 78 | 84 | 96 | 108 | 124 | 140 | 156 | 172 | 192 | 212 |

| dk | Max (Smooth) | 33 | 36 | 40 | 45 | 50 | 54 | 63 | 72 | 84 | 96 | 108 | 120 | 135 | 150 |

| Max (Knurl*) | 33.39 | 36.39 | 40.39 | 45.39 | 50.39 | 54.46 | 63.46 | 72.46 | 84.54 | 96.54 | 108.54 | 120.54 | 135.63 | 150.63 | |

| Min | 32.61 | 35.61 | 39.61 | 44.61 | 49.61 | 53.54 | 62.54 | 71.54 | 83.46 | 95.46 | 107.46 | 119.46 | 134.37 | 149.37 | |

| ds | Max | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 |

| Min | 21.67 | 23.67 | 26.67 | 29.67 | 32.61 | 35.61 | 41.61 | 47.61 | 55.54 | 63.54 | 71.54 | 79.54 | 89.46 | 99.46 | |

| k | Max | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 |

| Min | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 41.38 | 47.38 | 56.26 | 63.26 | 71.26 | 79.26 | 89.13 | 99.13 | |

| s | Na suna | 17 | 19 | 19 | 22 | 24 | 27 | 32 | 36 | 41 | 46 | 55 | 65 | 75 | 85 |

| Min | 17.05 | 19.065 | 19.065 | 22.065 | 24.065 | 27.065 | 32.08 | 36.08 | 41.08 | 46.08 | 55.1 | 65.1 | 75.1 | 85.12 | |

| Max | 17.23 | 19.275 | 19.275 | 22.275 | 24.275 | 27.275 | 32.33 | 36.33 | 41.33 | 46.33 | 55.4 | 65.4 | 75.4 | 85.47 | |

| t | Min | 11 | 12 | 13.5 | 15.5 | 18 | 19 | 24 | 28 | 34 | 38 | 43 | 48 | 54 | 60 |

| Tsawon zaren = b | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

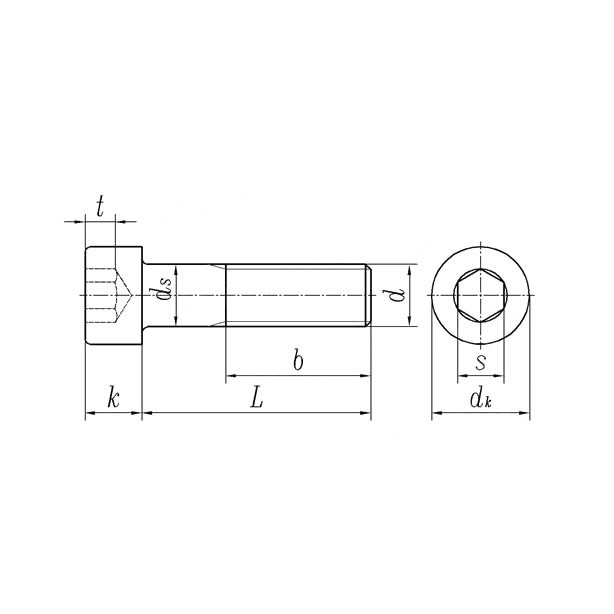

Zane daki-daki

Menene bambanci tsakanin Copper, Brass, Bronze?

Copper, Brass da Bronze, in ba haka ba da aka sani da "Red Metals", na iya zama iri ɗaya da farko. Amma hakika suna da bambanci da yawa a cikin kashi, aiki da sauransu.

Copper

Ana amfani da Copper a cikin nau'o'in samfurori masu yawa saboda kyakkyawan yanayin wutar lantarki da yanayin zafi, ƙarfin mai kyau, kyakkyawan tsari da juriya ga lalata. Ana ƙera kayan aikin bututu da bututu da yawa daga waɗannan karafa saboda juriyar lalata su. Ana iya siyar da su da sauri kuma a ɗaure su, kuma da yawa ana iya walda su ta hanyar iskar gas, baka da hanyoyin juriya. Ana iya goge su kuma a goge su zuwa kusan kowane nau'in rubutu da haske da ake so.

Akwai maki na Copper wanda ba a haɗa shi ba, kuma suna iya bambanta cikin adadin ƙazanta da ke ƙunshe. Ana amfani da makin jan ƙarfe mara iskar oxygen musamman a cikin ayyuka inda ake buƙatar babban aiki da ductility.

Ɗaya daga cikin mahimman abubuwan jan ƙarfe shine ikonsa na yaki da kwayoyin cuta. Bayan gwaje-gwaje masu yawa na rigakafin ƙwayoyin cuta da Hukumar Kare Muhalli ta yi, an gano cewa an gano cewa an gano nau'ikan ƙarfe 355 na tagulla, gami da tagulla masu yawa, sun kashe fiye da kashi 99.9% na ƙwayoyin cuta a cikin sa'o'i biyu na haɗuwa. An gano tabarbarewar al'ada ba don lalata tasirin ƙwayoyin cuta ba.

Aikace-aikacen Copper

Copper yana daya daga cikin karafa na farko da aka gano. Girkawa da Romawa sun sanya shi kayan aiki ko kayan ado, har ma akwai cikakkun bayanai na tarihi da ke nuna yadda ake amfani da tagulla don bakar raunuka da tsarkake ruwan sha. A yau an fi samun sa a cikin kayan lantarki irin su wiring saboda iya sarrafa wutar lantarki yadda ya kamata.

Brass

Brass galibi shine gami da ya ƙunshi jan ƙarfe tare da ƙara zinc. Brass na iya samun nau'ikan zinc ko wasu abubuwan da aka ƙara. Waɗannan nau'ikan gaurayawan suna haifar da fa'ida ta kaddarorin da bambancin launi. Ƙara yawan adadin zinc yana samar da kayan aiki tare da ingantaccen ƙarfi da ductility. Brass na iya kewayo cikin launi daga ja zuwa rawaya dangane da adadin zinc da aka ƙara zuwa gami.

Idan abun ciki na zinc na tagulla ya bambanta daga 32% zuwa 39%, zai ƙara ƙarfin aiki mai zafi amma aikin sanyi zai iyakance.

Idan tagulla ta ƙunshi fiye da 39% zinc (misali - Muntz Metal), zai sami ƙarfi mafi girma da ƙananan ductility (a dakin zafin jiki).

Aikace-aikacen Brass

Brass yawanci ana amfani dashi don kayan ado da farko saboda kamanninsa da zinari. Har ila yau, ana amfani da shi don kera kayan kida saboda yawan aiki da karko.

Tagulla

Bronze wani abu ne wanda ya ƙunshi farko da tagulla tare da ƙari na sauran kayan aiki. A mafi yawan lokuta abin da ake ƙarawa shine yawanci tin, amma arsenic, phosphorus, aluminum, manganese, da silicon kuma ana iya amfani dashi don samar da abubuwa daban-daban a cikin kayan. Duk waɗannan sinadarai suna samar da gawa mai ƙarfi fiye da jan ƙarfe kaɗai.

Bronze yana siffanta shi da launin zinare. Hakanan zaka iya bambanta tsakanin tagulla da tagulla saboda tagulla za ta sami zobba masu raɗaɗi a saman sa.

Aikace-aikace na Bronze

Ana amfani da tagulla wajen gina sassaka, kayan kida da lambobin yabo, kuma a aikace-aikacen masana'antu kamar bushings da bearings, inda ƙarancin ƙarfen sa akan juzu'in ƙarfe yana da fa'ida. Bronze kuma yana da aikace-aikacen ruwa saboda juriyar lalata.

Shiryawa

Game da mu

* Zane mai zuwa yana gano mabambantan incoterms ciniki. Da fatan za a zaɓi wanda kuka fi so.

KYAUTA-SAYAYYA

Ingancin Farko, Garantin Tsaro