DIN7991 Hex Socket Countersunk Screw Grade Carbon Karfe Zinc Plated Grade 8.8 10.9

DIN7991 Hex Socket Countersunk Screw Grade Carbon Karfe Zinc Plated Grade 8.8 10.9

Bayani

SANARWAMartani

SANARWAMagana

SANARWABayarwa

SHIRYE SHIRYE SHIRKA

10000+ SKU a cikin sito

Mun ƙaddamar da abubuwan RTS:

70% abubuwan da aka kawo cikin kwanaki 5

80% abubuwan da aka kawo cikin kwanaki 7

90% abubuwan da aka kawocikin kwanaki 10

Babban umarni, da fatan za a tuntuɓi sabis na abokin ciniki

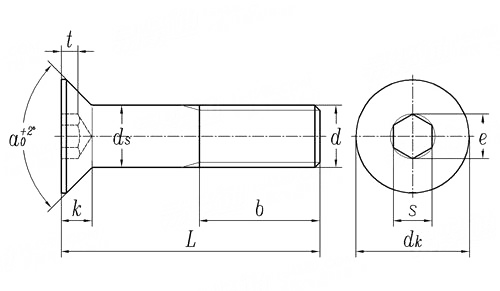

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | |

| P | Fita | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| α | (+2) | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 60° | 60° |

| b | L≤125mm | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125 ml ≤ 200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L >200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | Max=Na'am | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| Min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| ds | Max=Na'am | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Min | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | |

| e | Min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | 16 | 16 |

| k | Max | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | Na suna | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| Min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | |

| Max | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | |

| t | Max=Na'am | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| Min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9.87 | |

Cikakken bayanin

Babban ƙarfi fasteners za su samar da crispness lokacin da galvanized. Bukatar kulawa ta musamman.

Ruwan ruwa na hydrogen yawanci ana siffanta shi da jinkirin karaya a ƙarƙashin damuwa. An sami maɓuɓɓugan mota, wanki, sukurori, maɓuɓɓugan ruwa da sauran sassan galvanized, a cikin 'yan sa'o'i bayan an rushe taro, raguwar kashi 40% ~ 50%. A cikin tsarin yin amfani da sassa na musamman da aka yi da cadmium, an sami karyewar batch, kuma an warware wata matsala mai mahimmanci ta ƙasa kuma an tsara tsari mai tsauri. Bugu da kari, akwai wasu hydrogen embrittlement ba ya nuna jinkirta karaya sabon abu, kamar: electroplating hanger (karfe waya, jan karfe waya) saboda da yawa sau na electroplating da pickling plating, hydrogen shigar ne mafi tsanani, sau da yawa ya bayyana a amfani da ninki zai faru gaggautsa sabon abu; Maƙarƙashiyar bindigar, bayan sau da yawa na chroming, ya faɗi ƙasa ya karye; Wasu sassan da aka kashe (babban damuwa na ciki) za su fashe yayin da ake tsinke. Waɗannan sassan suna da tsananin hydrogenated kuma suna fashe ba tare da damuwa na waje ba, waɗanda ba za a iya amfani da su ba don dawo da taurin asali ta rashin ruwa.

Mafi girman ƙarfin abu, mafi girman haɓakar haɓakar hydrogen. Wannan shine ainihin ra'ayi wanda dole ne a fayyace shi ta hanyar masu fasaha na jiyya a saman yayin tattara ƙayyadaddun tsari na lantarki. Karfe tare da ƙarfi mai ƙarfi σb> 105kg / mm2 da ake buƙata ta ƙa'idodin ƙasa da ƙasa ya kamata a shayar da damuwa da pre-plating da kuma bayan-plating dehydrogenation magani daidai. Masana'antar zirga-zirgar jiragen sama ta Faransa tana buƙatar daidaitaccen maganin dehydrogenation don sassan ƙarfe tare da ƙarfin yawan amfanin ƙasa σs>90kg/mm2.

Saboda kyakkyawar ma'amala tsakanin ƙarfin ƙarfe da taurin, ya fi fahimta da dacewa don yin hukunci akan yanayin haɓakar hydrogen embrittlement na abu ta ƙarfi fiye da ƙarfi. Domin cikakkiyar zane-zanen samfuri da aikin injin ya kamata a yi alama da taurin ƙarfe. A cikin na'urar lantarki, mun gano cewa taurin karfe a kusa da HRC38 ya fara nuna hadarin karaya na hydrogen embrittlement. Don sassa sama da HRC43, ya kamata a yi la'akari da dehydrogenation bayan plating. Lokacin da taurin ya kasance game da HRC60, dole ne a yi maganin dehydrogenation nan da nan bayan jiyya na saman, in ba haka ba sassan karfe za su fashe a cikin 'yan sa'o'i.

Shiryawa

Game da mu

* Zane mai zuwa yana gano mabambantan incoterms na kasuwanci. Da fatan za a zaɓi wanda kuka fi so.

KYAUTA-SAYAYYA

Ingancin Farko, Garantin Tsaro